Introduction:

Formal footwear are an vital thing of expert clothing, embodying fashion, sophistication, and sturdiness. They are worn for business meetings, formal occasions, and activities, making the fine in their layout and production crucial. In this blog, we can delve deep into the intricate way of formal shoe manufacturing, masking every stage in meticulous element. Whether you are a shoe fanatic or someone keen on expertise the enterprise, this guide gives a step-thru-step walkthrough of approaches formal footwear are crafted.

1. Materials Selection

The first step in formal shoe production is deciding on super materials. The maximum usually used materials for formal shoes are leather-based-primarily based, artificial options, and from time to time cloth. Each cloth plays a key characteristic in figuring out the shoe’s durability, consolation, and appearance. Let’s damage down a few commonplace materials:

Leather: Full-grain leather is desired for its sturdiness, breathability, and conventional aesthetic. It’s sourced specially from cows, goats, or incredible animals like crocodiles for immoderate-give up shoes.

Synthetic Materials: These are used as cost-effective alternatives to leather, supplying versatility and being extra eco-friendly in some instances.

Sole Materials: The sole may be crafted from rubber, leather-based, or a aggregate of each. Rubber soles provide greater grip and are water resistant, while leather-based soles provide a proper, fashionable end.

2. Pattern Creation

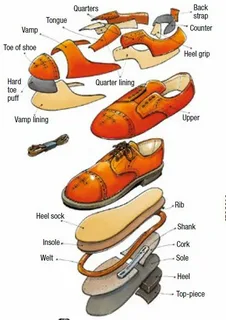

Once the materials are determined on, the subsequent step is to create the shoe pattern. This includes designing every a part of the shoe on paper, so one can then be used as a template. The sample consists of:

Upper Part: Covers the pinnacle of the foot, often crafted from leather-based-based totally or first-rate fabric.

Vamp and Quarter: These are the primary parts of the top, which encompass the lace section and the edges of the shoe.

Heel and Toe: Extra reinforcement is frequently added here to hold the shoe’s form and offer manual.

This pattern-making technique requires precision and interest to detail, as even a small misalignment can affect the shoe’s wholesome.

3. Cutting the Materials

After the pattern has been mounted, the selected materials are cut into the specified shapes. This manner is done either manually by skilled employees or thru machines in huge-scale manufacturing setups. The slicing must be accurate due to the fact uneven or misaligned portions can result in manufacturing waste or substandard footwear.

Upper and Lower Part Cutting: The leather or fabric is lessen to form the better a part of the shoe, even as thicker materials, which include rubber or leather-based, are reduce to shape the only.

4. Stitching and Assembly

Once the materials are reduce, they may be stitched collectively. This is a meticulous manner, because it determines the general creation and sturdiness of the shoe.

Upper Stitching: The top additives (vamp, quarters, and tongue) are sewn together the usage of long lasting threads. This requires professional those who make sure that the stitches are uniform and tight to avoid any loose threads or weak spots.

Lining: The lining is added to the indoors of the shoe to offer consolation. The lining may be fabricated from leather or a gentle cloth material, depending on the emblem or sort of shoe.

Sole Attachment: After sewing the better parts, the best is attached. For leather-based soles, they’ll be glued or stitched. Rubber soles are normally bonded the use of immoderate-grade adhesives, despite the fact that some producers pick out stitching for delivered sturdiness.

5. Lasting Process

The “final” is a mold that offers the shoe its shape. The pinnacle elements of the shoe are located around the closing and then stretched to make sure a comfortable match. This technique guarantees that the shoe retains its form inside the course of its lifespan.

Hand Lasting vs. Machine Lasting: In excessive-cease shoe manufacturing, the lasting approach is regularly achieved by means of hand, which leads to better-becoming shoes. Machine lasting is faster and extra not unusual in mass manufacturing.

Toe and Heel Shaping: Special interest is given to the toe and heel sooner or later of lasting to make certain they’ve got the proper shape and symmetry.

6. Sole and Heel Attachment

The attachment of the best and heel is crucial for the shoe’s sturdiness and aesthetic appeal.

Goodyear Welt Construction: This is the maximum durable technique for attaching the only to the top. A strip of leather-based (the welt) is sewn to both the pinnacle and the handiest, bearing in mind the only to be replaced whilst it wears out.

Cemented Construction: The sole is glued to the pinnacle without any stitching. While this technique is quicker and further fee-effective, it could not be as long lasting as Goodyear welting.

Heel Attachment: After the sole is hooked up, the heel is affixed to the bottom of the handiest, both thru nails or glue. In high-give up shoes, the heel also can be stitched for delivered power.

7. Finishing

Once the best and heel are connected, the shoe undergoes a completing way. This is wherein the shoe is polished, the rims are trimmed, and any imperfections are corrected.

Polishing and Buffing: The leather-based is polished using fantastic waxes and creams to provide it a shine. This technique additionally situations the leather, preventing it from drying out or cracking.

Edge Trimming: Any more cloth from the sewing or sole attachment is trimmed off, ensuring a neat and smooth look.

Final Inspection: Each shoe is thoroughly inspected for any flaws, which includes unfastened stitches, uneven soles, or imperfections inside the leather.

8. Quality Control

Quality manipulate is a key part of formal shoe production. Shoes undergo numerous rounds of inspection at unique degrees of producing. From checking the stitching accuracy to assessing the great of the polish, each detail is scrutinized.

Comfort Testing: The footwear are tested for consolation with the aid of putting them on a version or dummy toes. If important, adjustments are made to make sure the right healthy.

Durability Testing: This includes checking out the shoe’s sole for flexibility and checking the top for resistance to place on and tear.

9. Packaging and Shipping

Once the footwear have handed the exceptional manipulate degree, they are packaged for cargo. High-stop formal shoes are frequently packed in defensive wrapping with branded containers. Packaging is designed to prevent damage during transportation.

Branding: Many manufacturers encompass a branded dust bag or polishing material with their footwear.

Eco-Friendly Packaging: Some producers are transferring towards the use of recyclable or biodegradable substances for his or her packaging to reduce environmental impact.

Conclusion:

Formal shoes production is an in depth manner that calls for precision, extremely good materials, and expert craftsmanship. From material preference to very last packaging, every degree contributes to developing a product that now not excellent appears stylish however also gives consolation and sturdiness. Whether it’s the elaborate pattern creation, lasting technique, or the very last polish, every step is vital to producing formal footwear that stand the check of time.